Solutions

A Smarter Way to Process Oil & Gas

Scalable diesel production at the point of use, without the complexity or cost of traditional refining.

Think Energy Holdings proprietary processing plant transforms crude oil and condensates into high-efficiency diesel, on-site or near-use, reducing supply chain challenges and cost. Our modular plants deploy in as little as 90 days, offering a fast, flexible alternative to conventional refining infrastructure.

Whether you're powering remote operations or solving for local supply resilience, Think Energy Holdings delivers supply security, lower cost, cleaner product, and operational control, on your terms.

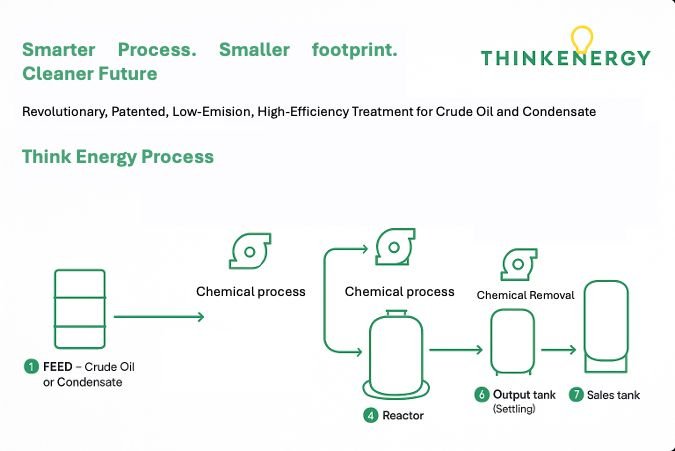

Think Energy Holdings developed groundbreaking and patented technology to solve for midstream bottlenecks that make procuring a reliable supply of high quality diesel difficult and expensive. The technology is an organic chemical process that transforms Oil & Gas into diesel in a small modular reactor facility.

The facility is installed near the point of production or consumption, eliminating the requirement to transport feedstock to a traditional refinery, removing a great deal of cost and complexity in the process.

Oil & Gas producers and industrial operators—acquire a dedicated facility and enjoy full control of the process and all the quality, reliability and cost advantages.

Key Benefits:

No Midstream Bottlenecks: Process closer to production or demand, not limited by pipeline and refining availability

Modular & Scalable: Deploy in 90 days on a 2-acre footprint, modular for scalability

Energy Security: Eliminate dependency on external refineries, control the process with a dedicated facility

Ultra-Low Emissions: Meets strictest global H2S standards, 50% CO2 reduction

Technology Validated: The technology has been validated by respected research teams and the product has been proven in the marketplace with millions of gallons produced and sold